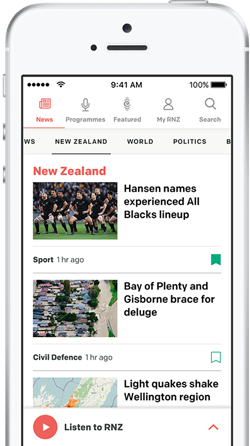

Nelson MP Rachel Boyack opening the new AGB factory in Tasman. Photo: RNZ/Samantha Gee

A New Zealand stone fabricator is calling on manufacturers and consumers to end the use of potentially deadly crystalline-silica engineered stone.

About 1000 workers are thought to have been been exposed to high concentrations of respirable crystalline-silica dust while working with engineered stone slabs during the past 15 years.

The product has been banned in Australia and while the New Zealand government considers tighter controls, AGB Stone - one of the country's largest fabricators - has already made the switch to zero-silica engineered stone and is calling on others to do the same.

The company has been manufacturing bench tops for 18 years and has now opened the country's first zero-crystalline-silica engineered stone fabrication factory in Tasman.

Co-owner Cam Paranthoiene said the business was no longer using high silica engineered stone after the ban in Australia.

"We went to investigate zero-silica [products] commercially because we lost a big contract, but once we found out the impact on the staff in Australia, we knew that we had to do the same thing for our staff here. We've proven that this product works, so why have that risk?" Paranthoiene said.

Zero-silica products now made up 60 percent of AGB's orders and the plan was to convert the company's six other factories to zero-crystalline-silica over time, he said.

"This is a milestone day for our industry, that we can run a zero silica engineered stone plant. So, where are the governance people? Where are the people that are trying to solve silicosis in New Zealand? Why aren't they standing right here going 'well done'?"

AGB Stone co-owner Cam Paranthoiene. Photo: RNZ/Samantha Gee

How many people have been affected by working with engineered stone?

Engineered stone used in benchtops and flooring has a high silica content. Those working with it may be exposed to respirable crystalline-silica (RCS) dust while cutting, grinding, sanding and polishing the stone. Exposure can lead to a progressive respiratory disease called accelerated silicosis.

An ACC spokesperson said since 2019 the Ministry of Health, WorkSafe and ACC had advised people who had worked with engineered stone for six months or more in the last ten years to have a health check at their GP or medical provider, who could refer them for tests to assess for accelerated silicosis.

An ACC claim could then be lodged on the basis of exposure, not diagnosis.

Data from ACC showed there had been 253 claims lodged as of 15 August for assessment of accelerated silicosis since the corporation's assessment pathway came into effect in September 2020.

Of those, 30 were accepted for cover and most were for simple or complex silicosis, not accelerated silicosis.

But research published in March by the Public Health Communication Centre found in past 15 years about 1000 NZ workers had been exposed to high concentrations of RCS dust while working with engineered stone slabs.

It said, applying Australian data, 250 of the 1000 New Zealand workers who had fabricated engineered stone in the past 15 years would develop silica-related diseases.

AGB has opened the country's first zero crystalline silica engineered stone fabrication factory in the Tasman District. Photo: RNZ/Samantha Gee

What are we doing about it?

The government is reviewing options to control the health risks associated with engineered stone.

Earlier this year, the Ministry of Business, Innovation and Employment (MBIE) consulted on various control measures - including a potential ban - while WorkSafe NZ lowered the workplace exposure standard for silica dust and updated guidance for businesses.

The Employers and Manufacturers' Association, The Council of Trade Unions and MinEx - the national health and safety council for New Zealand's extractive sector - had advocated for it to be banned.

MBIE sectoral health and safety policy manager Nita Zodgekar said it received 68 submissions from businesses and organisations during public consultation on options to control the risks from engineered stone and other sources of exposure to respirable crystalline silica.

It had now provided advice to Workplace Relations and Safety Minister Brooke van Velden.

Zodgekar said any workers who came into contact with RCS were potentially at risk of developing health issues, with approximately 80,000 workers experiencing probable high levels of exposure.

That included a range of industries such as construction and demolition and activities like cutting and grinding concrete products.

It estimated between 600 and 900 workers in engineered stone fabrication were significantly exposed to an elevated risk of silica-related disease.

Van Velden said the government needed to used an evidence-based approach when making decisions around engineered stone.

Several initiatives had been established to encourage businesses to improve their risk management practices, she said.

WorkSafe had conducted inspections in workplaces fabricating engineered stone since 2019, published information for businesses and workers on RCS and silicosis, and reduced the workplace exposure standard for RCS in 2019 and again in 2023.

Inspectors reported businesses were now more aware of the risks of exposure to RCS and overall were managing those risks more effectively, van Velden said.

She was considering the advice from MBIE and would report back to cabinet on the proposed policy direction in due course.

Industry leading the change

Paranthoiene said major industry players should support the safer zero-silica product even though engineered stone products had not been banned in New Zealand.

AGB has opened the country's first zero crystalline silica engineered stone fabrication factory in the Tasman District. Photo: RNZ/Samantha Gee

AGB had spent the last 15 years instigating safer processes to manage the risks of silicosis.

It phased out high-crystalline silica products in 2023 and then introduced zero-crystalline silica engineered stone last year.

"If you're a good fabricator with really good disciplined systems and controls, you're okay, but not everyone is okay and that's the problem," he said.

"We have to look at this as being about the lowest common denominator in our industry. It's not the best people, it's the bottom end and generally the bottom end comes with the most vulnerable workers as well. So you get this double whammy of toxic product, poor systems and then poor application of those systems."

AGB had worked with kitchen hardware supplier Archant to find zero-silica stone products after the ban across the ditch and sales director Sefton Clare said now that was all they sold.

"We're just seeing the volumes of the zero-silica product increase going from strength to strength, it's really a no brainer," he said.

"When Australia banned engineered stone we just took the simple route and said that anything that's banned over there, we're over it, we're not going to continue with it."

Archant sales director Sefton Clare. Photo: RNZ/Samantha Gee

New Zealand should also ban the product, Clare said.

"We obviously don't know what the New Zealand government is going to do in this situation, but from a risk adverse perspective it just makes no sense at all to continue with products that they've got a cloud over them now, it's a much safer, easier choice to go for zero.

"One person with silicosis is one too many."

Nelson MP Rachel Boyack officially opened the new factory in Tasman on Monday and said it was good to see industry taking action where the government had not.

"We know that these products can cause silicosis for workers and that's devastating for them, so to have a zero-silica engineered stone factory - the first of its kind in New Zealand - operating here in Nelson, sends a really strong signal to the market."

Nelson MP Rachel Boyack opening the new AGB factory in Tasman. Photo: RNZ/Samantha Gee

New Zealand needed to do more to keep people safe at work, Boyack said.

"Likewise customers actually need to take some responsibility in terms of the products that they're choosing to purchase. There has been publicity around these products so when you're making your purchase you should be checking what is the silica quantity within the product and ideally choosing a zero silica product."

Sign up for Ngā Pitopito Kōrero, a daily newsletter curated by our editors and delivered straight to your inbox every weekday.